How Automation at Twin Engineers has helped an SME win big!

Twin Engineers is a 25-year old Indian supplier, manufacturer, and exporter of some innovative equipment that addresses key industry segments like Automotive, Electrical and Electronics, Composites, Packaging and PU Products. The organization offers its best-in-class products in Meter Mmix Dispensing, Single-Component Dispensers, Robotic sealant dispensers, Oil and Fluid filling, and Adhesive Dispensers. The company has a reputed global clientele in its years of service with clients including much of India’s Automotive sector Tata Motors, Ford, Suzuki,Honda, Volvo, etc.

Back in 2008, the Indian automotive parts market was estimated to be nearly US $26B. The nation has continued experiencing persistent growth in the sector for a decade after that too. Around that time, an automobile filter manufacturer from Delhi had connected with us for its aftermarket products. The dealer wanted to introduce a process strong-enough to increase manufacturing efficiency tenfold so they could make a real impact in the growing Automotive business.

How we confronted this challenge

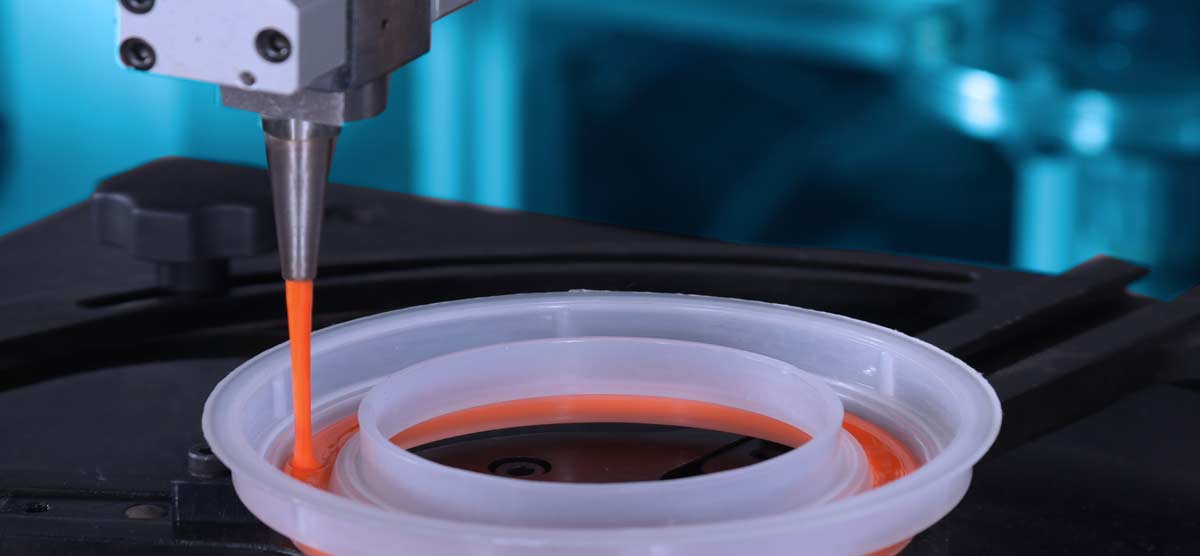

The automotive parts dealer was looking to manufacture filters with a semi-automated machine capable of PU Foam dispensing. But it was not easy to convince them to adopt our solution. Filter prices were subject to intense competition and labour was cheap -not a situation conducive to large budgets. We faced rejection on our first quote but with persistence, several meetings, and visits to the factory, we helped define a new understanding of the value of automating the meter mix dispensing process for the customer.

The solution suggested by Twin Engineers

Based on our understanding the market demand and growth opportunities for the business, Twin’s team suggested to the customer to think big. We recommended that they drop the idea for a basic machine and, instead, we suggested that they go in for a fully-automated dispensing system.

The new proposal did not get a positive response for months. The Sales team continued discussions and spent more time to grasp the customer’s concern. The customer was concerned about support and we instilled the confidence that we would support them till the machine proved itself on the production line. With the risk of failure now greatly reduced the customer decided to go ahead.

The first machine for the company went operational in about 3 months. Our team was actively involved in training the unskilled operators at the company to ensure proper quality and throughput. Handholding by Twin’s team ensured a confident Operator and Production staff that felt ready to take-off with their new Machine.

The next step

One year down the line the Machine had paid itself off. The customer got back to us, this time with lots of ideas to further advance thed automation and features in the Machines.

We were only happy to oblige. The second machine went operational .. then the third and the journey has continued over the past decade. The client’s business expanded, profits increased, and capacities increased. This helped to transform the company into a leading brand in aftermarket filters in the extremely competitive North Indian territory.

The future

Last year, the customer invited us to help assess their expansion plan. With help from Twin’s innovative machines, the Client’s operations have always been among the most profitable in the industry. In a wonderful moment, the founder of the company thanked our team while proudly mentioning that he had bought his first Mercedes recently.

"“Automation is a prerequisite for quality-controlled and efficient manufacturing!”."

Automation, once it became the cornerstone of manufacturing, has the potential to make a significant contribution to the expansion plans of small and medium-sized companies. Further, automation brings several advantages such as increased production rate without any compromise on the quality, economical and efficient use of raw materials at every stage of production, and enhanced safety procedures.

Traditionally, small and medium enterprises have been held back from their Automation plans through fear of making a sizeable investment. However, as this story shows, taking the plunge in a planned manner can help recoup the investment with time. In that quest, innovative manufacturers such as Twin Engineers who have helped more than 250 small and medium entrepreneurs, can help prove that automation is not a luxury -in fact, it could help these businesses get a little bit of luxury (like a Mercedes) into their lives.