Vacuum potting is a specialized technique to achieve the highest quality and reliability in potted electronic assemblies. Normally, vacuum potting is done for the high voltage applications. However, given that electronic circuits are now getting smaller and smaller, so is the space available for potting compounds to enter the components. For over 30 years, Twin has gained immense expertise in handling a variety of vacuum potting applications. Learning from this experience, we have identified 5 common mistakes that many customers tend to overlook in vacuum potting.

This was known to the Indian manufacturer mentioned above, and thus, they approached Twin to proactively to resolve their challenges in vacuum potting.

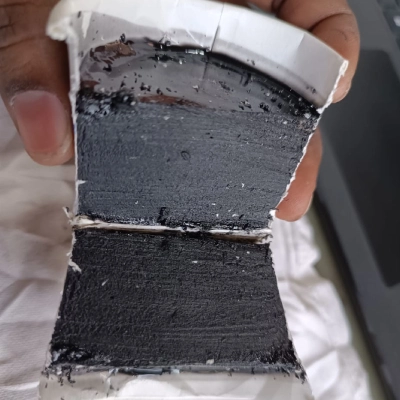

1. Avoid the smallest air bubbles. Make small changes in the design.

2. Insufficient Vacuum Level Rapid Vacuum Release

3. Inadequate Material Degassing

4. Dispensing overflow

5. Ignoring Atmospheric Conditions

6. Pre and Post Process Checks

Additional Tips

Training and Documentation

Ensure all personnel involved in the vacuum potting process are adequately trained and that detailed documentation of the process is maintained for consistency and quality control.

Regular Maintenance

Keep vacuum potting equipment well-maintained to avoid unexpected failures and ensure consistent performance.

Choose your machine with our Expert

Sanchita Bhalwankar

Expert in Potting Processes

- +91 99755 49703

- mktg@twinengineers.com