When a "Better & Cheaper" Machine Became a Costly Mistake

How Twin Saved an EMS Manufacturer from 2 Years of Potting Failures

The Urge to Buy Cheap and its hidden costs

For this leading EMS manufacturer, the decision seemed like a no-brainer. A local supplier promised a potting automation with lots of features at a lower price.

On paper, it had superior specs, more automation, and cost 30% less than Twin’s Machine. But once installed on the shop floor, the problems started piling up.

It looked like a smart investment—until they started using it.

The urge to buy cheaphad backfired—badly.

The Problem: When a Cheaper Machine Becomes Your Biggest Expense

This wasn’t just a Machine failure—it was a failure of expectation vs. reality.

Vacuum Wasn’t Just About the Pump – The system never achieved the required vacuum levels, leading to air bubbles, weak insulation, and unreliable parts.

Mixing Failures – Adhesive ratios weren’t maintained, leading to inconsistent curing and high rejection rates.

Automation Didn’t Mean Productivity – The machine had more features but slower performance, reducing shift output by 25%.

Support did not have the expertise – The supplier delivered the machine. Their support struggled, leaving the customer’s production team struggling for months.

What looked like a cost-saving move turned into an expensive mistake—lost time, high rejection, and mounting waste.

How Twin Fixed It: The Right Machine, The Right support

When Twin stepped in, we didn’t sell a bigger or more expensive machine. We simply asked:

What’s the real problem?

Instead of features that impress, we focused on engineering that delivers results:

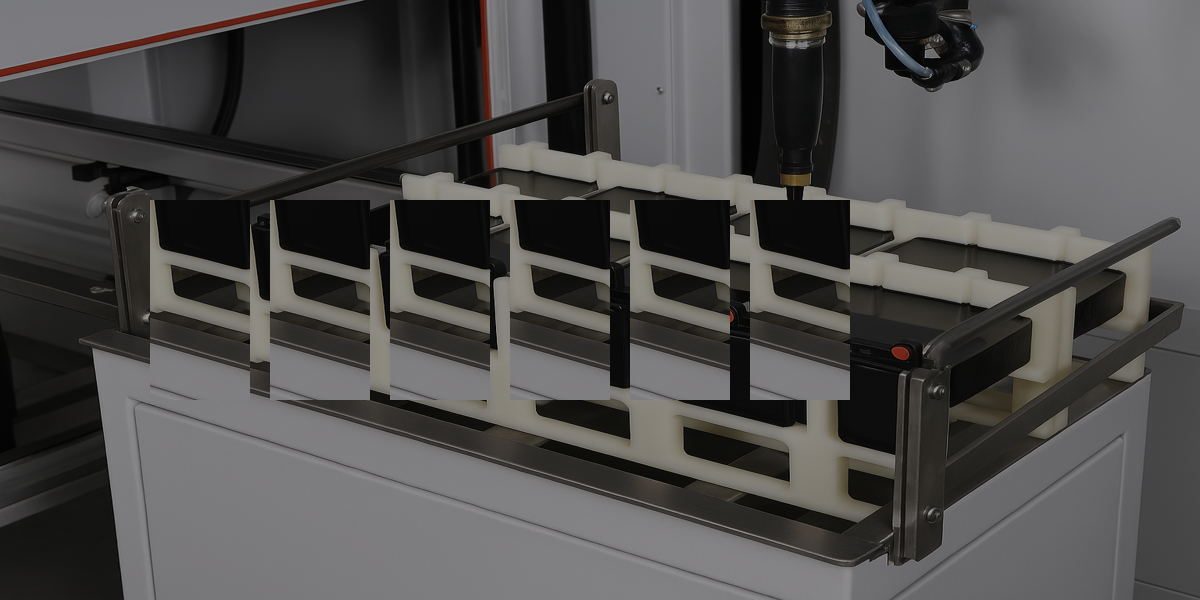

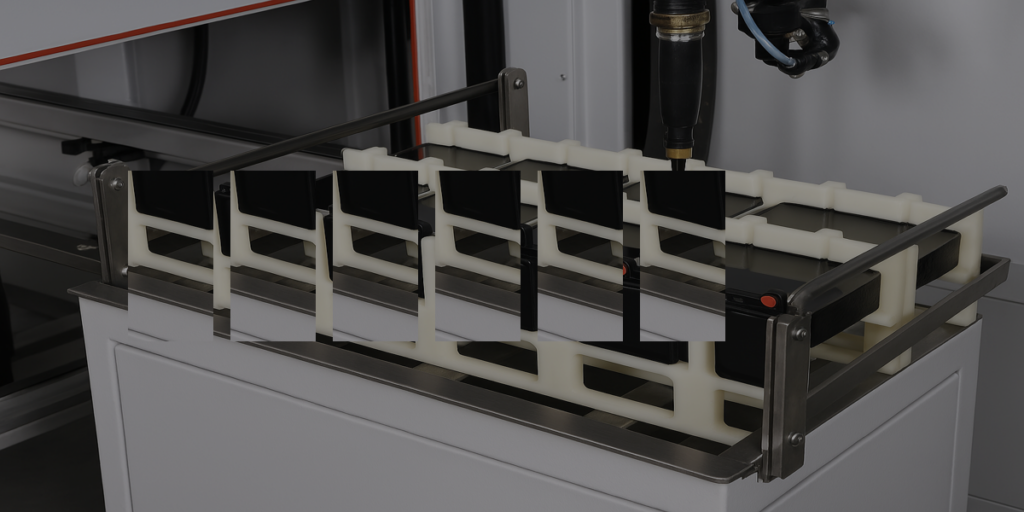

A machine built for results— we focused on the right vacuum, precise mixing, and precise dispensing.

We didn’t blame the operators—we stood with them for getting the right potting for the first time. Instead of frustration, we showed them how the machine could make their job easier, reduce headaches, and get them home on time.

A system that adapts to production reality – Operator-friendly controls, faster output, and better material handling—everything was designed to work in their process, not just in theory.

And the difference? Immediate.

The Impact: The Real Cost of Cheap vs. The Value of Expertise

30% rejection eliminated instantly

20% Production output increased –

Up and running from Day 1

No Hidden Costs – The machine paid for itself in saved material, labor, and time.

Today, we are talking about repeat orders for the Machine.

Key Takeaway: A Better, Cheaper Machine Isn’t Always a Better Solution

The biggest mistake in selecting your potting machine? Buying based on price.

This EMS manufacturer learned it the hard way—until Twin gave them a machine that actually delivered.

If you’re thinking about cost, think beyond the price tag—think about the real cost of delays, rework, and lost production.

Twin knows the field realities. We’ve walked this path a thousand times—and we know what works.

Still think a cheaper machine saves you money? Let’s talk before it costs you millions.

Client's Challenge: When Cheaper Became Costlier

- Low-cost, feature-rich machine – Promised high specs but failed in production.

- Vacuum & mixing failures – Weak insulation, air bubbles, and rejection.

- Slow performance, 25% less output – More features, less productivity.

- Poor support – Supplier struggled, operators left frustrated.

Twin's Approach: Fixing What Really Matters

- Focus on results, not features – Built a machine for real production needs.

- Hands-on operator support – Reduced effort, faster learning, zero stress.

- Adaptable system, faster output – Designed for their process, not assumptions.

- Consistent vacuum and precise mixing – Eliminated defects and ensured reliability.

The Results: Real Savings, Real Success

- 30% rejection eliminated – First-time-right production.

- 20% increase in output – Faster, more reliable performance.

- Up and running from Day 1 – No delays, no hidden costs.

- Repeat orders rolling in – Proof that success scales.