2K Pack Pump for Adhesive Dispensing in Solventless Lamination

Saves Adhesives, Manpower and guarantees high performance at lowest operating costs

Twin’s 2K Pack Pump for adhesive dispensing is designed to cater to high flow rate needs in the lamination process and is suitable to mix materials with wide range of viscosity. The Mixers come with advanced electronic controls, precision metering gear pumps, heated hoses and on the fly GSM calculations.

Applications

Consumer Goods

Food

Key Benefits

Auto-refil System from 200 L Drums

Ultrasonic level sensor to continuously monitor NCO/OH level in the pump tanks

Minimum & maximum levels for NCO/OH can be set

LED indicator & buzzer for minimum level of NCO/OH in 2K pump

Insulated heated hoses to retain the temperature of NCO during transfer

Silica gel breather to keep the material moisture-free

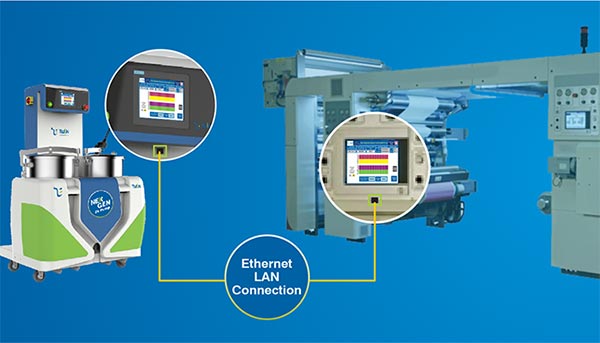

Connect your Laminator with Twin’s Pack Pump

Automated GSM control

Saves material by quickly adjusting the Laminator speed as per on-line GSM calculations

Single screen control

To monitor and operate the key parameters on Laminator and Pack Pump

Technical Specifications

| Floor Area | 1.3m (L) X 0.8m (W) X 1.5m (H) |

| Pneumatic | Compressed Air (6 bar) |

| Flow Rate | 4.8 LPM and 8 LPM (for 1:1 ratio) |

| Tank Size | 60 Ltr. |

| Power | 3 Phase, 440 VAC, 50 Hz (Connected Load 2.5 Kw) |

| Suitable for | Laminator speed – Up to 500 mts/min Material viscosities – More than 20k cps |