Trickle Impregnation for insulating motors. Automatic and clean process.

For EV Motors, Hub Motors, BSG, IPM, BLDC, Synchronous Motors

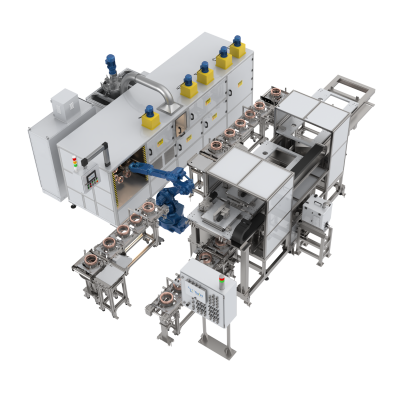

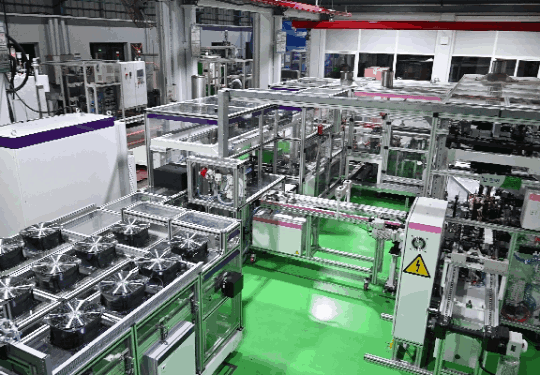

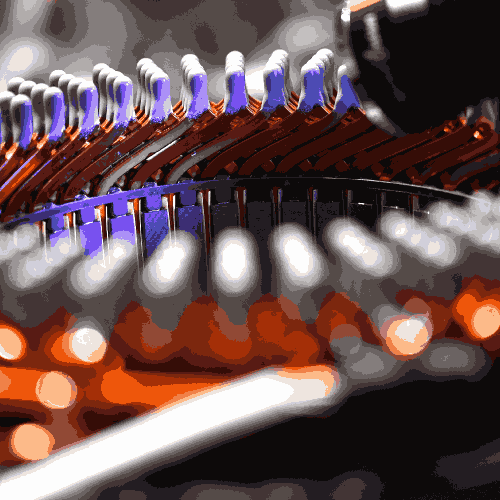

Trickle Varnish Impregnation Plants

for Hub Motor, BSG, IPM BLDC, Synchronous Motor

Total solution for high volume production, at low operating costs.

Pre-heating, Powder Coating, Dispensing,Curing & Cooling proces for shortest cycle time

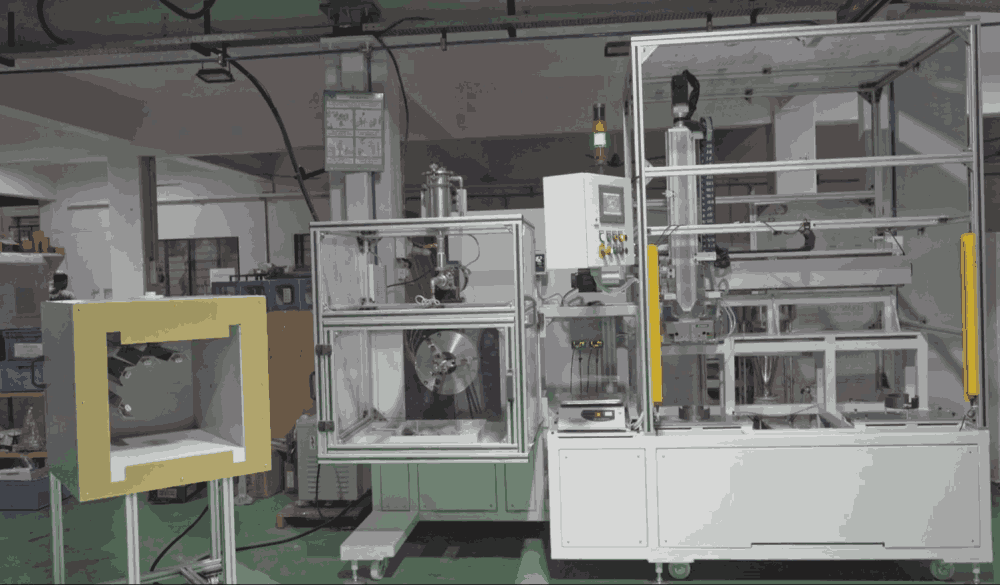

Standalone System for Protoyping, or specialised motors

Integration

Pre-Heating, Powder Coating

Stator Length

Up to 200 mm

Output

Up to 50 motors/shift

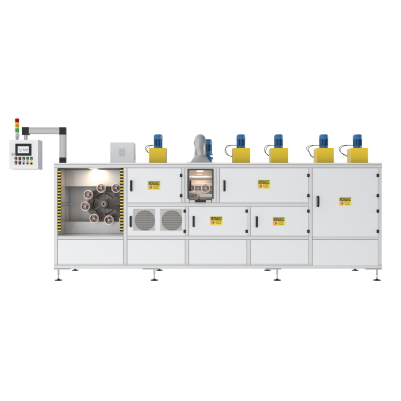

Fully Automated Trickling Plant

Integration

Pre-Heating, Powder Coating

Stator Length

Up to 330 mm

Output

Up to 250 motors/shift

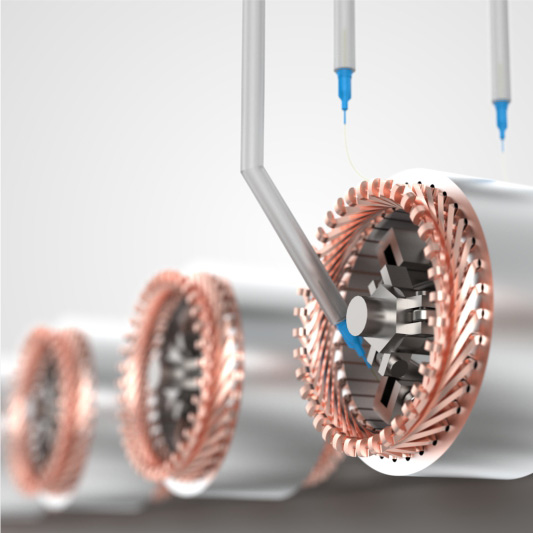

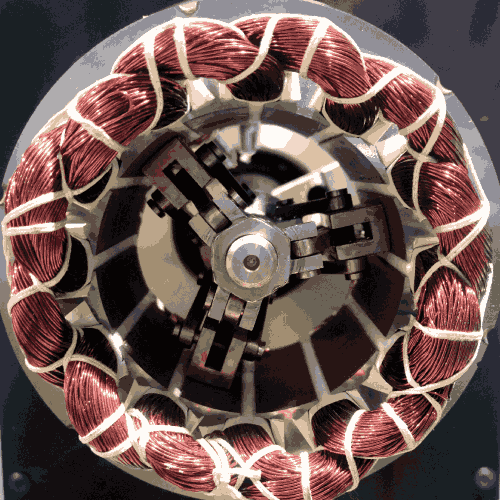

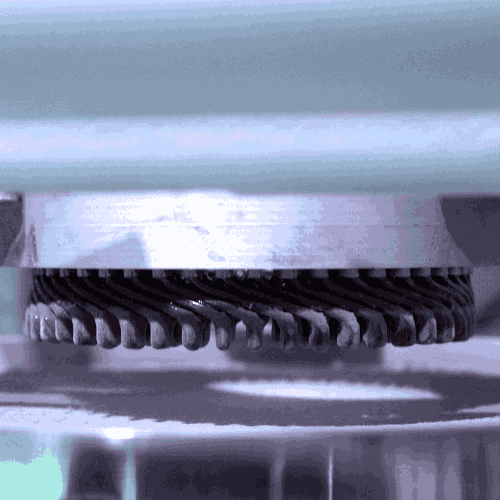

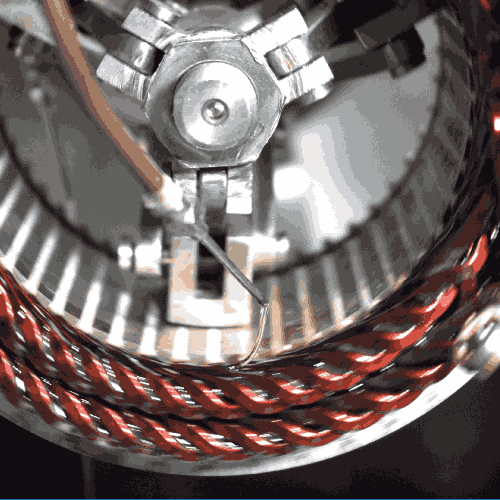

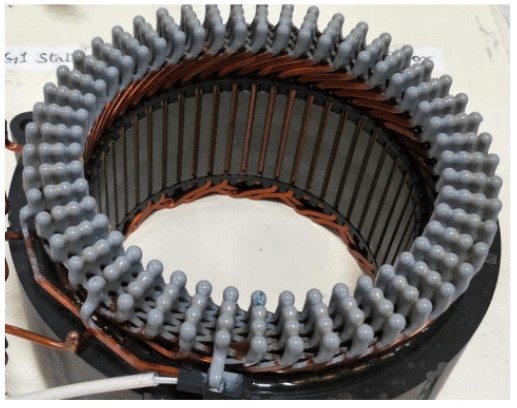

Excellent resin penetration in the whole winding. High bond strength. Uniform coating and balanced parts for your motors.

Twin has over 20+ years of experience in offering fully automated plants for tricke impregnation of epoxy resins for motors.

The system can apply the resin with maximum accuracy, ensuring maximum absorption and avoiding resin dropping from the parts. The technology used in our trickling systems complies with the best quality, reliability and automation standards.

Benefit from Twin's advanced dispensing technology

100% Penetration of Resin for complete protection

Integration with Powder Coating

Processing materials with wide range of viscosities

IoT for data management and preventive maintenance

Compact and modular systems with automation

Operator friendly, and programmable process recipes

Easy cleaning and maintenance

24 X 7 Service Support

Download Catalog 2024

Want to browse the entire range of our products at your leisure?

Get your FREE copy of the latest Product Catalog.

Complete range, customised to your needs

Not sure where to start

Gaining Competitive Advantage with Innovative Automation

•

April 12, 2024

How two large Electronic Component

Choose your machine with our Expert

Sanchita Bhalwankar

Expert in Motor Protection

- +91 99755 49703

- mktg@twinengineers.com