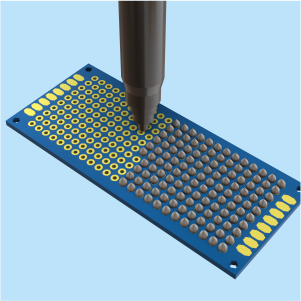

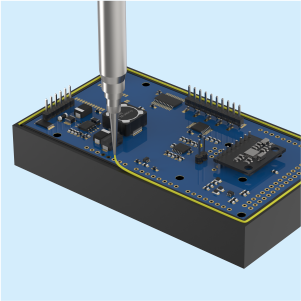

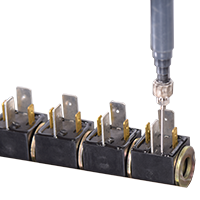

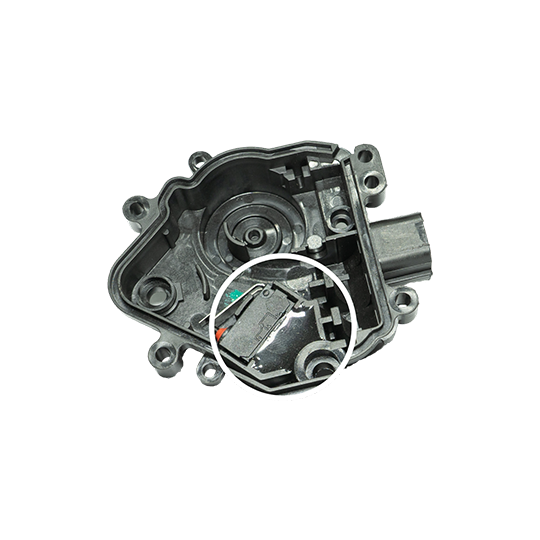

Meter Mix Dispensing Machines for Atmospheric Potting

for Sensors, ECUs, PCBs, LEDs, and many more..

Modal Box Title

Modal Box Content

Trickle Varnish Impregnation Plants

for Hub Motor, BSG, IPM BLDC, Synchronous Motor

Seamless at every scale.

Complete range of Machines for Wind-Blade Manufacturing

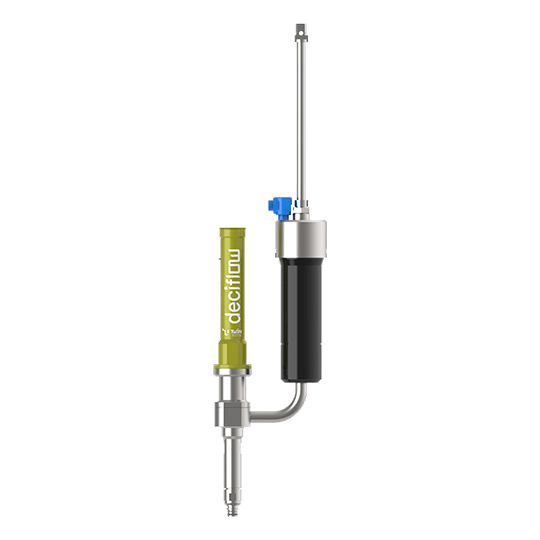

Single Component

Suitable material package

Cartridge or Tanks

Viscosity

Thixotropic to watery thin liquid

Flow Rate

0.2 gm/seconds

Pump with Controller

Suitable material package Suitalbe

Cartridge or Tanks

Flow Rate

0.2 gm/second

Mixing Ratio

100:5 to 100:100

Table Top Dispenser

Suitable material package

Tanks (0.5 L to 5 L)

Flow Rate

0.2 gm/second

Mixing Ratio

100:5 to 100:100

High-speed. Continuous Potting. 100% Accurate. For dispensing volume as low as 0.01 gms.

Whether it is about dispensing liquids or thick pastes, mixing materials with diverse viscosities, or ensuring high-precision, accurate, and repeatable dispensing, at high-speed, we have the solution that fits your goals and budgets.

Benefit from Twin's advanced mixing and dispensing technology

100% Bubble Free Potting

Variable Ratio Systems

Processing materials with wide range of viscosities

IoT for data management and preventive maintenance

Available with under vacuum potting

Operator friendly, and programmable process recipes

Easy cleaning and maintenance

24 X 7 Service Support

Download Catalog 2024

Want to browse the entire range of our products at your leisure?

Get your FREE copy of the latest Product Catalog.

Complete range, customised to your needs

Not sure where to start

Poor potting in motors can

Choose your machine with our Expert

Sanchita Bhalwankar

Expert in Potting Processes

- +91 99755 49703

- mktg@twinengineers.com