Epoxy Resin Impregnation and Adhesive Mixing

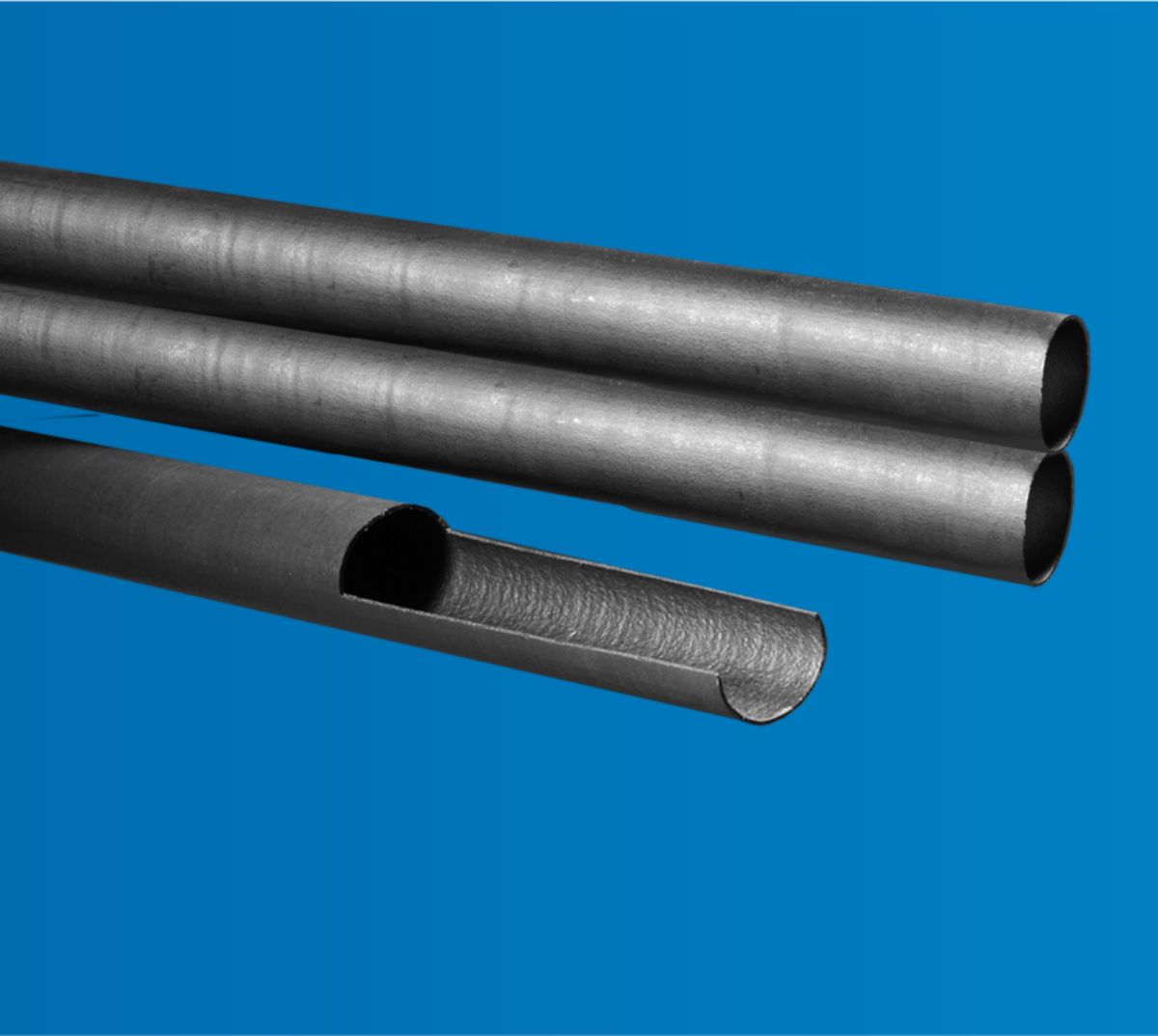

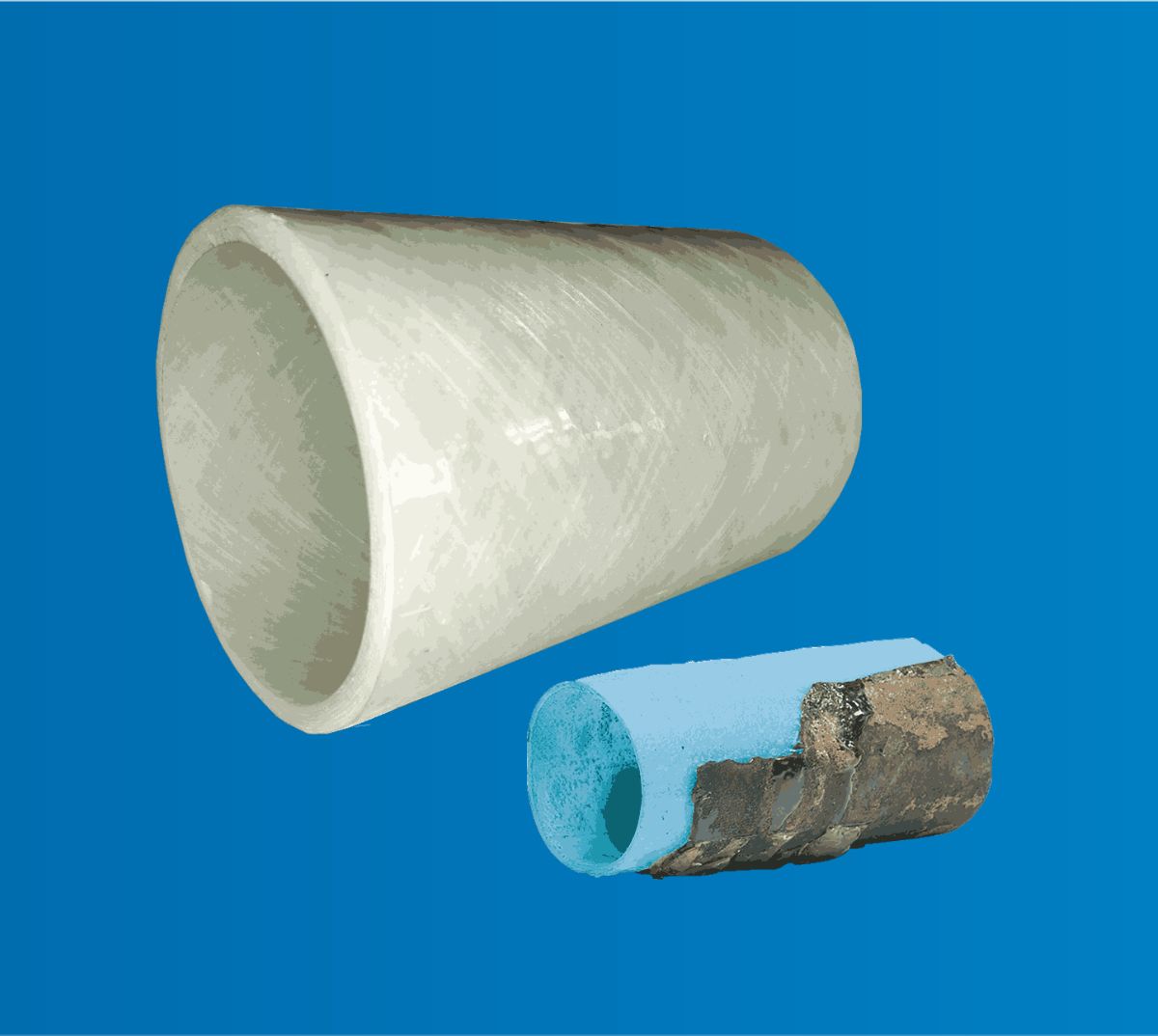

for Composite Cylinders, Pipes, Rods many more components ...

Trickle Varnish Impregnation Plants

for Hub Motor, BSG, IPM BLDC, Synchronous Motor

Seamless at every scale.

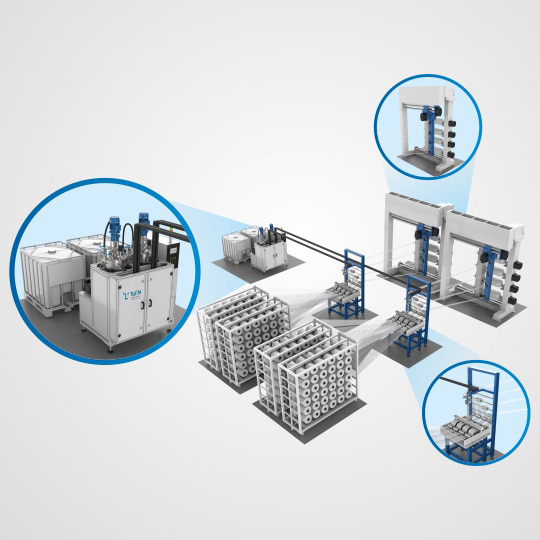

Complete range of Machines for Composite Manufacturing

Hand Layup Machine

Tanks

60 Ltr

Attachment

Extended Boom Structure

Flow Rate

2-5 Kg/min

Resin Infusion Machine

Flow Rate

1-20 Kg/min

Mixing Ratio

100:20 to 100:70

Options

IBCs or Direct Infusion

Automation Options

Total solution for zero rejections and rapid scale-up of your composite processes.

Twin’s Machines for epoxy dispensing and resin infusion for filament winding, pultrusion and infusion processes offers complete peace-of-mind with 100% reliability. From prototyping of components to large-scale production of composite parts, Twin’s expertise ensures your process goes live within weeks.

Benefit from Twin's advanced mixing and dispensing technology

100% Error Free Mixing for Zero Rejections

Variable Ratio Systems

Processing materials with wide range of viscosities

IoT for data management and preventive maintenance

Compact and flexible dispensing systems

Operator friendly, and programmable process recipes

Easy cleaning and maintenance

24 X 7 Service Support

Complete range, customised to your needs

- 100% Bubble free potting

- Save costs with over 80% reduction in rejections70%

- Time savings on product trials

- Eliminate 100% manual errors in dispensing

- Processing of media with wide range of viscosity

- Dispensing accuracy of ± 1%

- Repeatability of ± 99%

- PLC based controller

- Precision pumps for metering

- Suck-back gun

- Easy dispensing integration for handheld and automation options

Complete range, customised to your needs

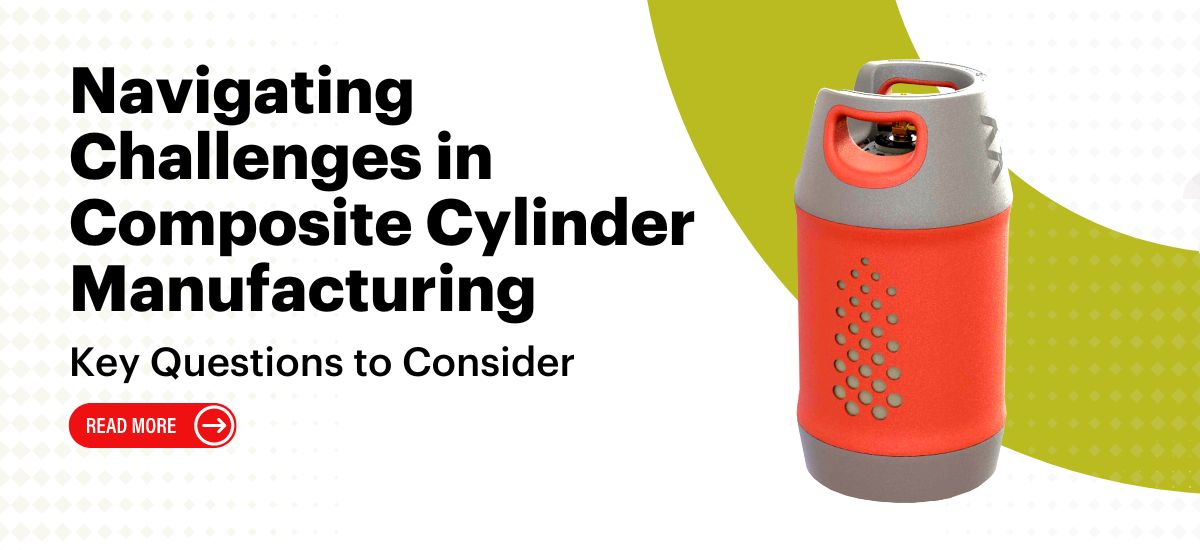

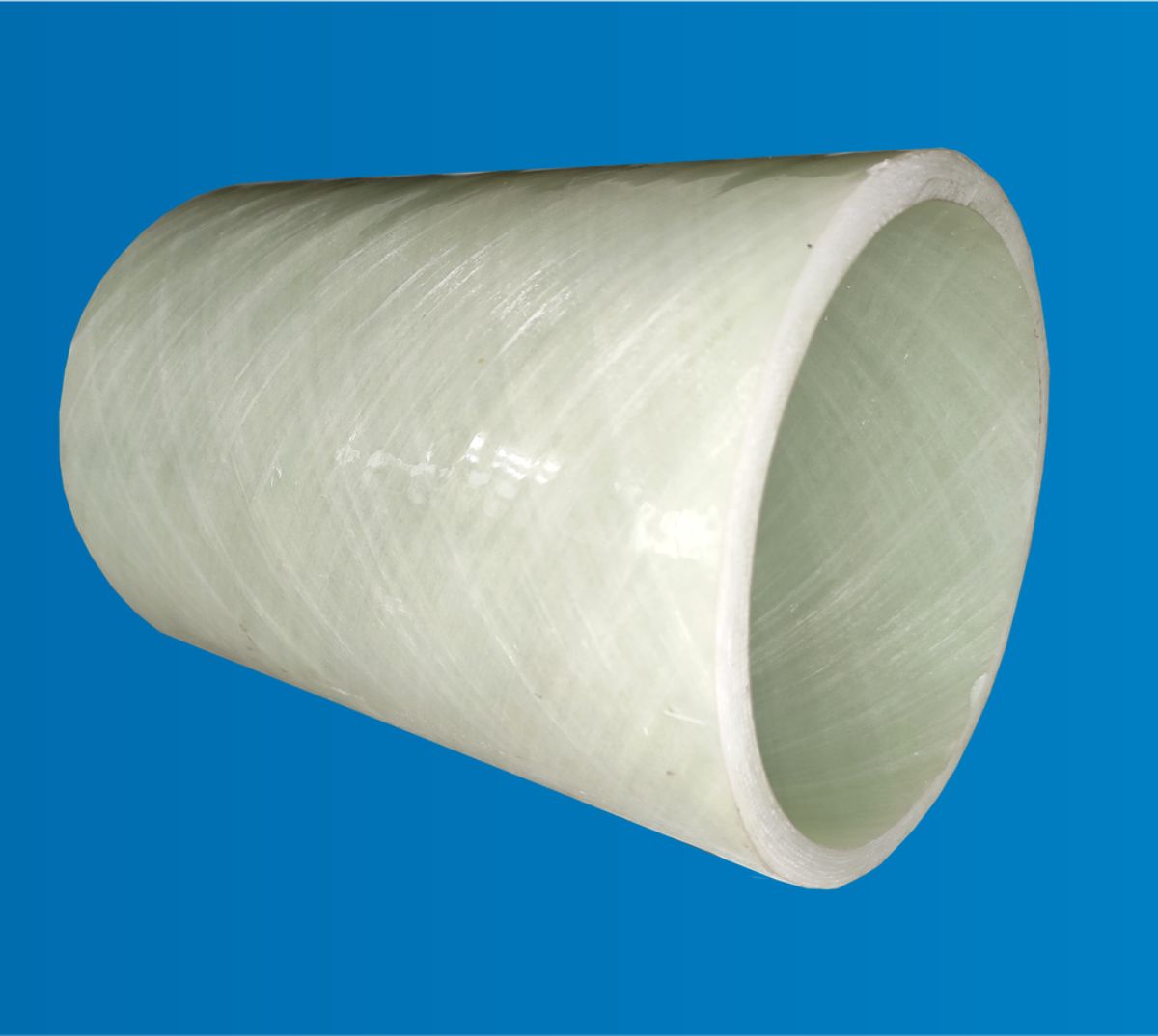

The manufacturing of composite cylinders,

Meet the Award Winner! Online Direct Infusion Machine

•

April 26, 2024

Twin Engineers proudly announces its

Tackling the 5 Challenges in Resin Infusion in Wind Rotor Blades

•

April 19, 2024

Wind blade manufacturers face significant

Choose your machine with our Expert

Sanchita Bhalwankar

Expert in Composite Processes

- +91 99755 49703

- mktg@twinengineers.com