Meter Mix Dispensing Machines for Atmospheric Potting

for Sensors, ECUs, PCBs, LEDs, and many more..

Modal Box Title

Modal Box Content

Trickle Varnish Impregnation Plants

for Hub Motor, BSG, IPM BLDC, Synchronous Motor

Precision potting at every scale

Total solution for PU, Epoxy and Silicone dispensing with automation

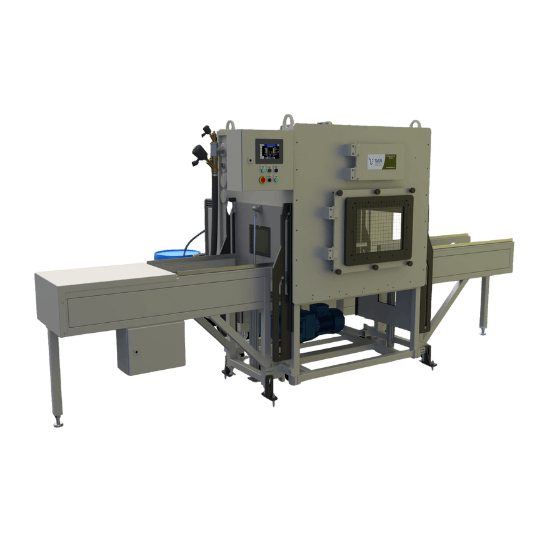

Fully Automatic Vacuum Potting

Tank Capacity

35 L | 60 L |100 L

Flow Rate

0.5 g/sec to 1kg/min

Vacuum Level

up to 5 mBar

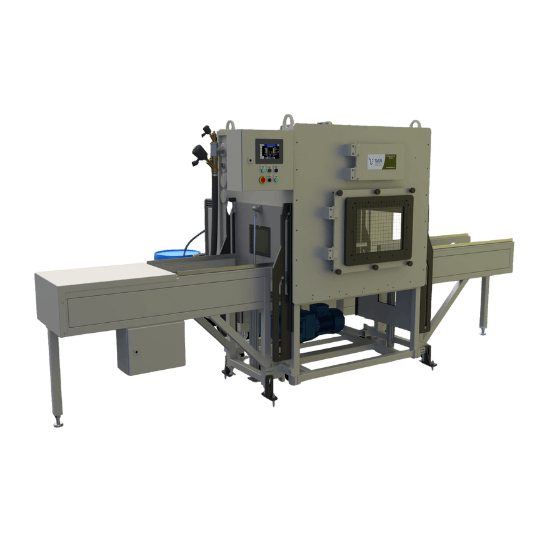

Semi Automatic Vacuum Potting

Tank Capacity

35 L | 60 L | 100 L

Flow Rate

0.5 g/sec to 1kg/min

Vaccum Level

up to 5 mBar

Get 100% Traceability and zero rejections in vacuum potting. Achieve high volume production with minimal labour.

Twin’s Extensive Range of Vacuum Potting and Degassing Machines are the first choice for customers owing to complete automation for single/multi-stage Vacuum Potting. The vacuum potting enables high-volume production without any manual intervention and with minimal labor for processes using Epoxy and PU. The range of automation options help to produce components in batches with accurate control over vacuum and 100% traceability.

Benefit from Twin's advanced mixing and dispensing technology

100% Bubble Free Potting

Variable Ratio Systems

Processing materials with wide range of viscosities

IoT for data management and preventive maintenance

Available with a range of Vacuum Chambers

Operator friendly, and programmable process recipes

Easy cleaning and maintenance

24 X 7 Service Support

Download Catalog 2024

Want to browse the entire range of our products at your leisure?

Get your FREE copy of the latest Product Catalog.

Complete range, customised to your needs

Not sure where to start

Gaining Competitive Advantage with Innovative Automation

•

April 12, 2024

How two large Electronic Component

Choose your machine with our Expert

Sanchita Bhalwankar

Expert in Potting Processes

- +91 99755 49703

- mktg@twinengineers.com