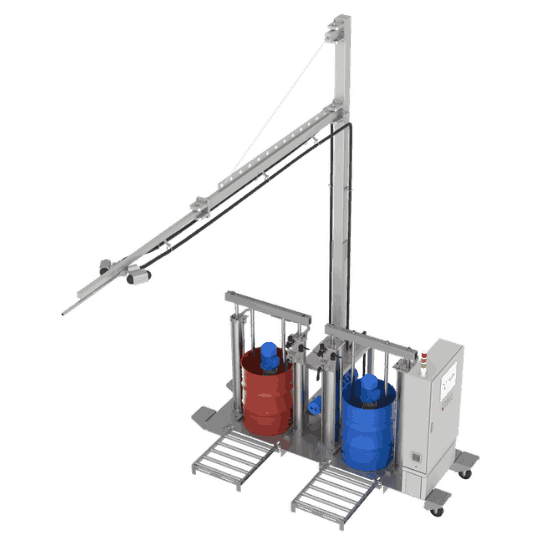

Accurate Mixing for two-part structural PU/ Epoxy paste adhesive for bonding composite wind turbine blades

For Blades up to 85 meters

Modal Box Title

Trickle Varnish Impregnation Plants

for Hub Motor, BSG, IPM BLDC, Synchronous Motor

Faster production with consistent adhesive properties

Proven systems for high structural integrity of wind rotor blades

Optimix

Flow Rate

5-12 Kg/min and 8-20 Kg/min

Mixing Ratio

100:20 to 100:100

Viscosity

upto 1 million cps at 25deg

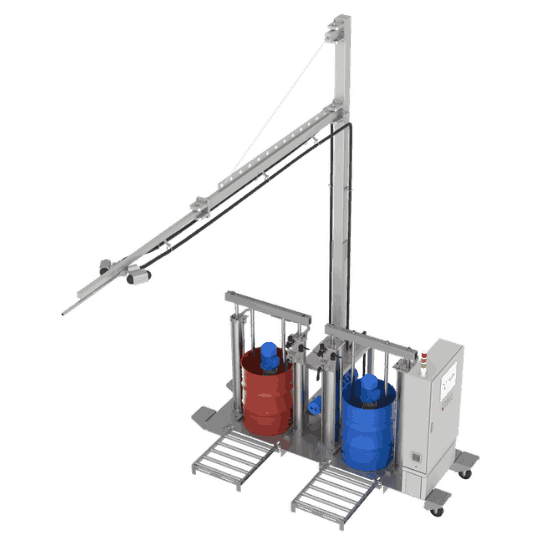

Intellomix

Flow Rate

5-12 Kg/min and 8-20 Kg/min

Mixing Ratio

100:20 to 100:100

Viscosity

upto 1 million cps at 25deg

Option

5 mtr boom with auto adjustable drive

High speed dispensing, and guaranteed bond strength with accurate mixing ratio

Twin’s meter mix dispensing systems for two component epoxy resin ensure accurate mixing ratio for the adhesives and are specially designed for high volume dispensing of the glue in stipulated time for bonding of shells and large composite structure.

Twin’s systems are well proven for the paste-like adhesives with viscosity up to 1 million cps. The systems are available in both, portable as well as stationary versions, as per the needs. The portable system can be moved in parallel to the blades during online application of adhesives.

Benefit from Twin's advanced mixing and dispensing technology

100% Accurate Mixing Ratio

Variable Ratio Systems

Processing materials with wide range of viscosities

IoT for data management and preventive maintenance

Clean, contamination-free process

Operator friendly, and programmable process recipes

Easy cleaning and maintenance

24 X 7 Service Support

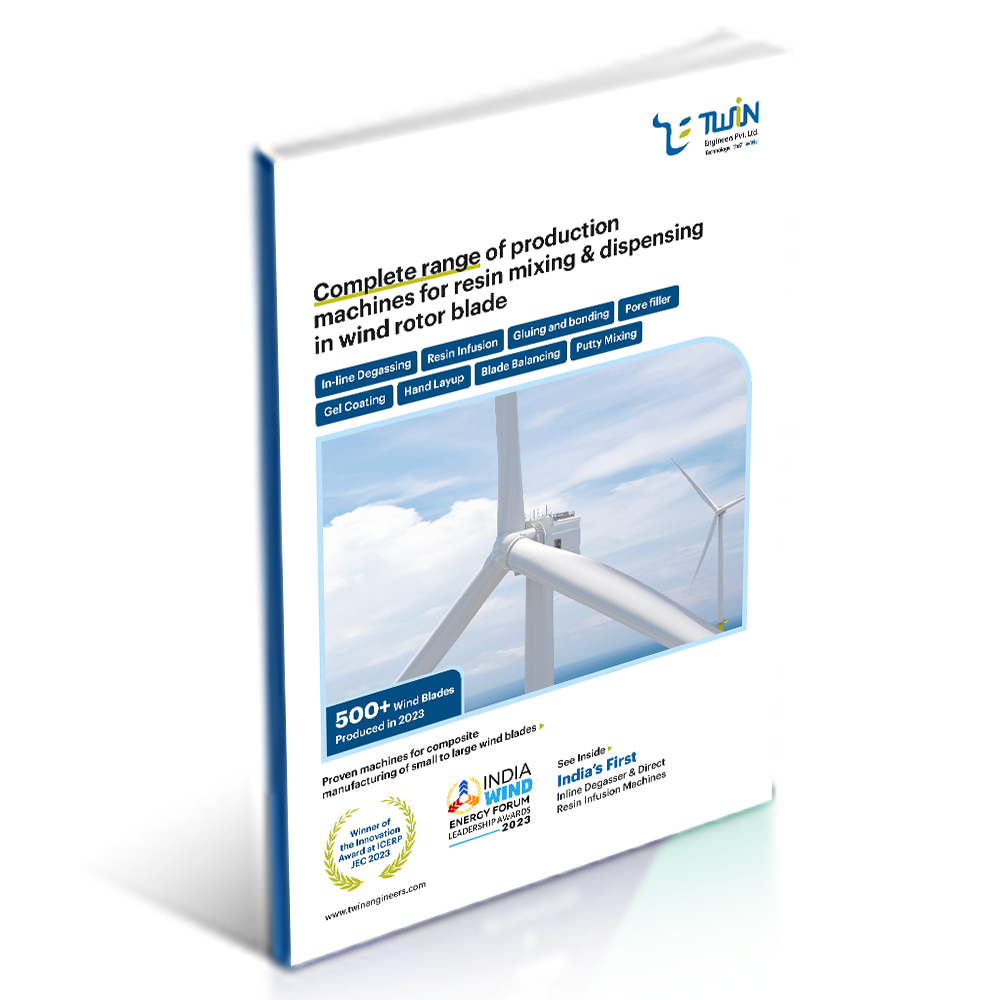

Download Catalog 2024

Want to browse the entire range of our products at your leisure?

Get your FREE copy of the latest Product Catalog.

Complete range, customised to your needs

Meet the Award Winner! Online Direct Infusion Machine

Twin Engineers proudly announces its

Tackling the 5 Challenges in Resin Infusion in Wind Rotor Blades

Wind blade manufacturers face significant

Choose your machine with our Expert

Sanchita Bhalwankar

Expert in Composite Processes

- +91 99755 49703

- mktg@twinengineers.com