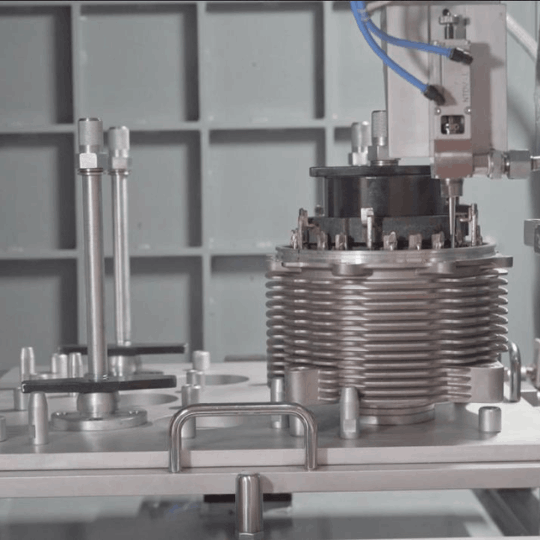

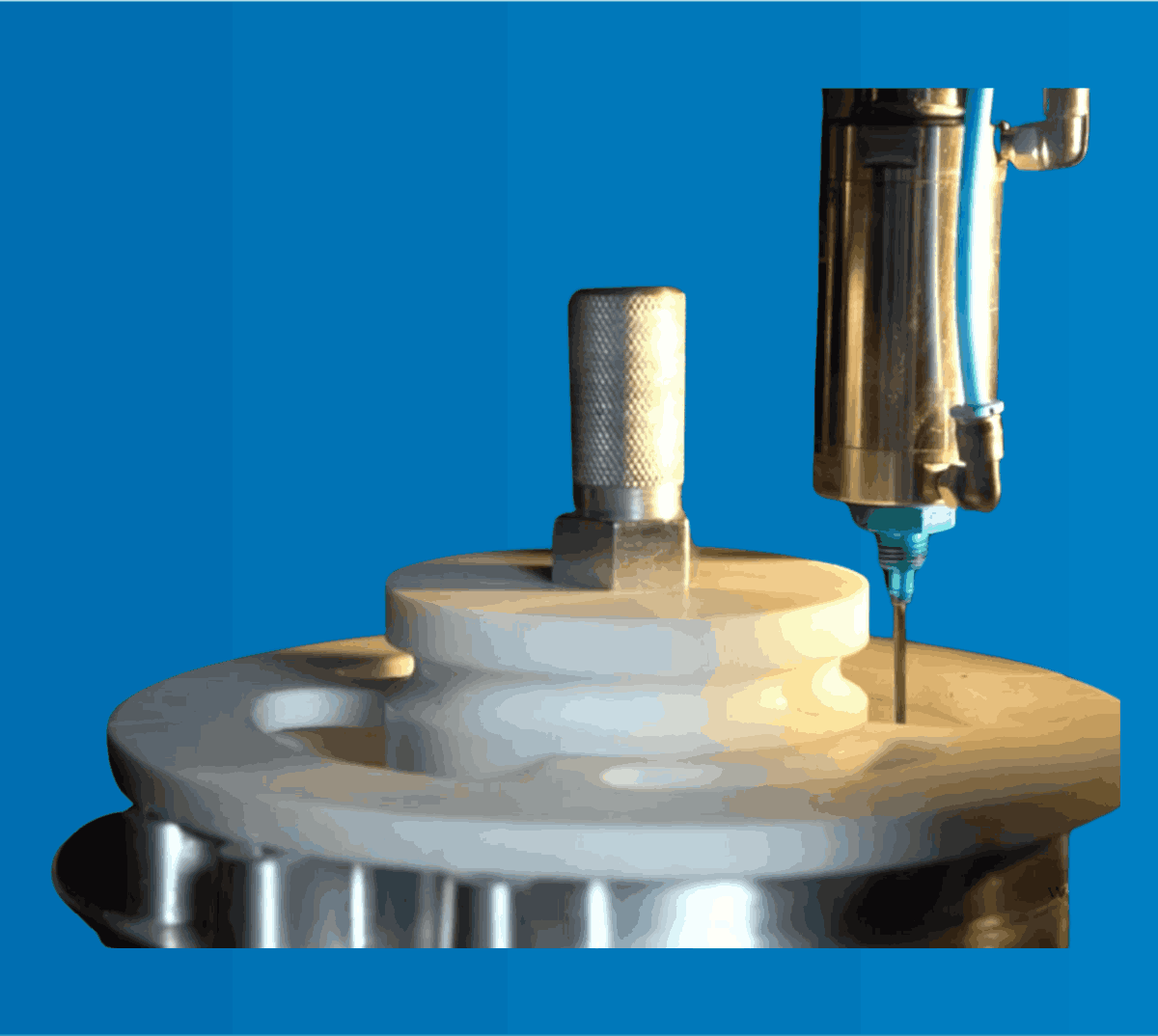

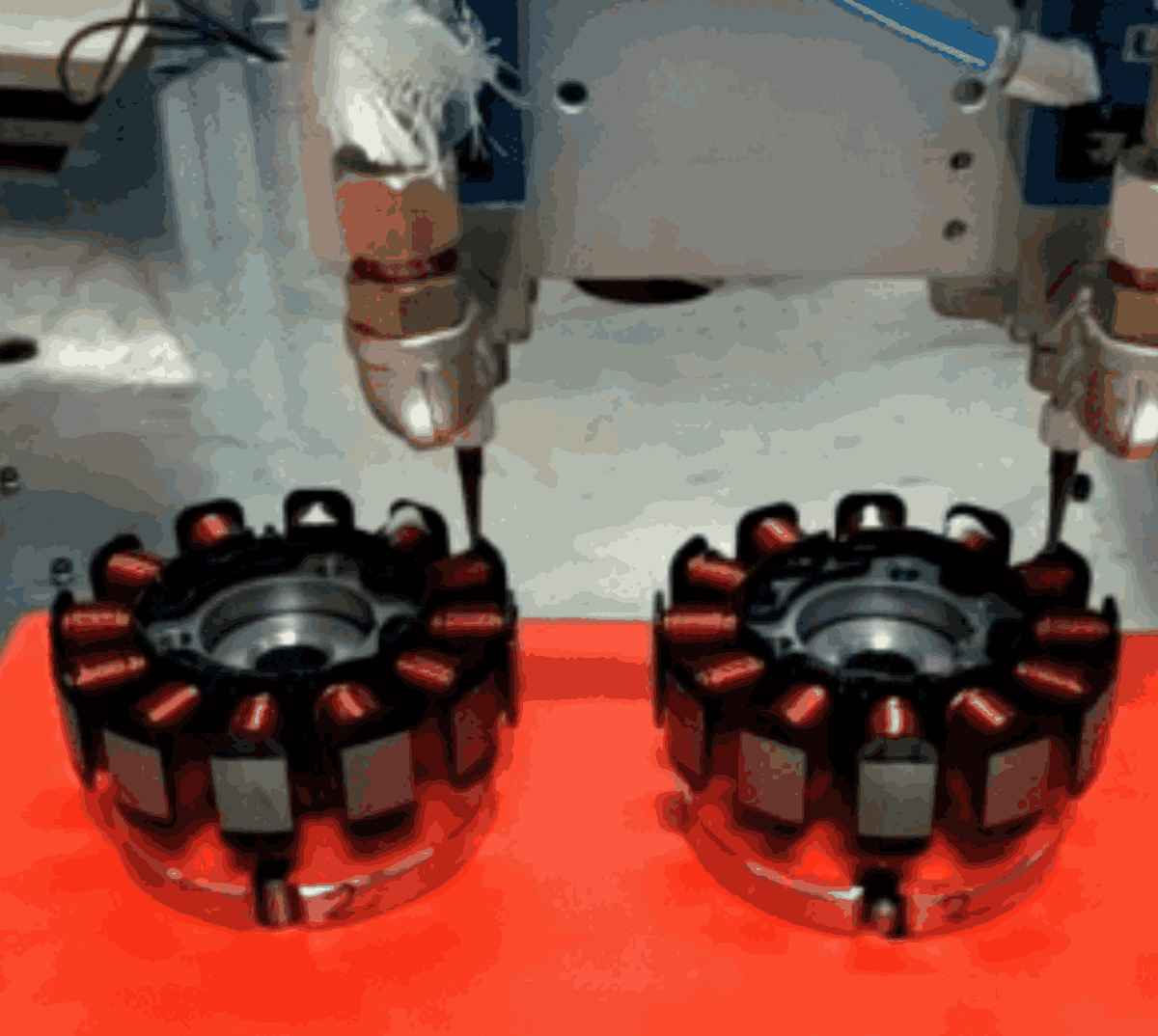

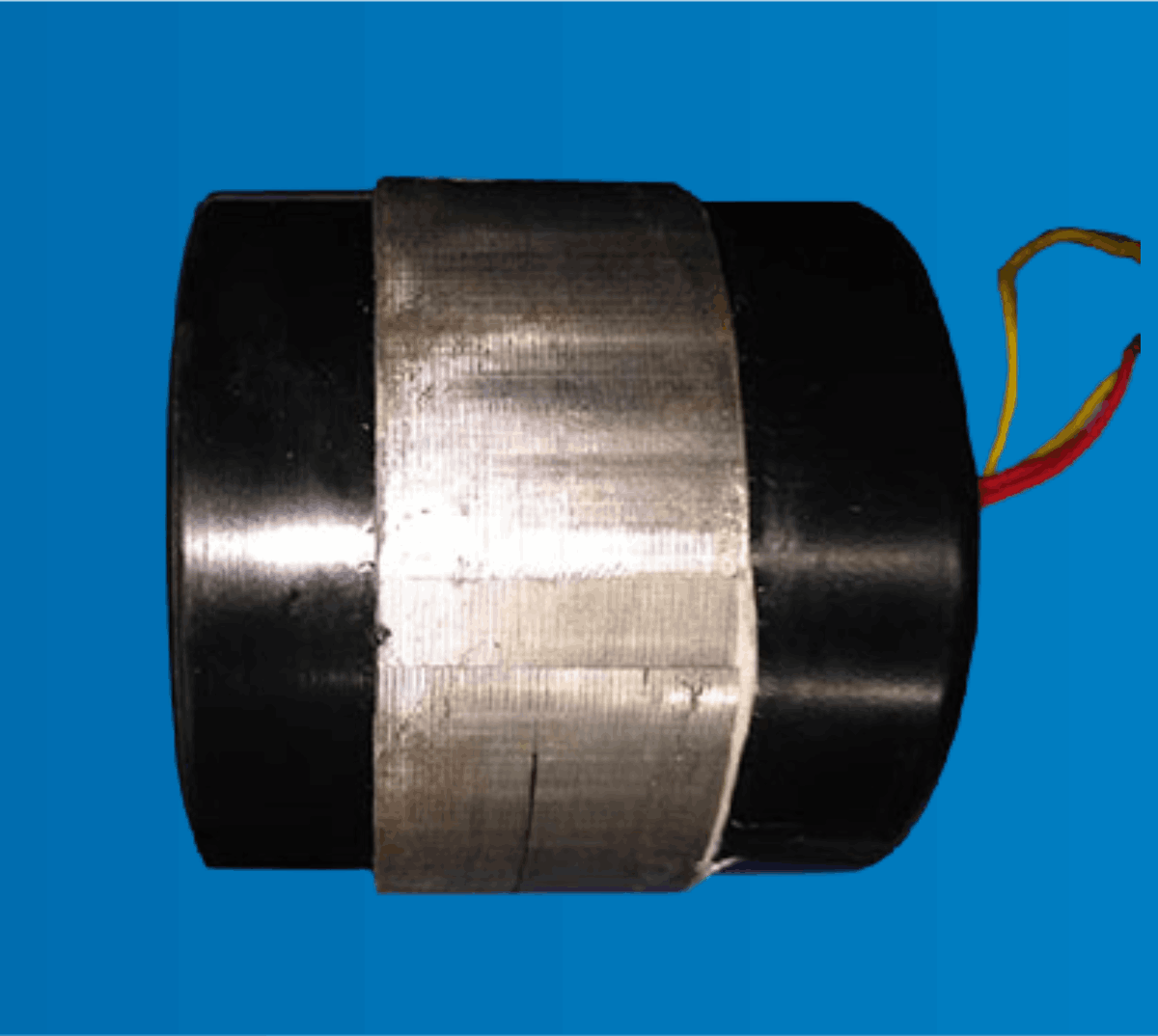

100% Void Free Potting. Accurate PU, Epoxy or Silcone Mix and guarantee of total penetration even for intricate coils.

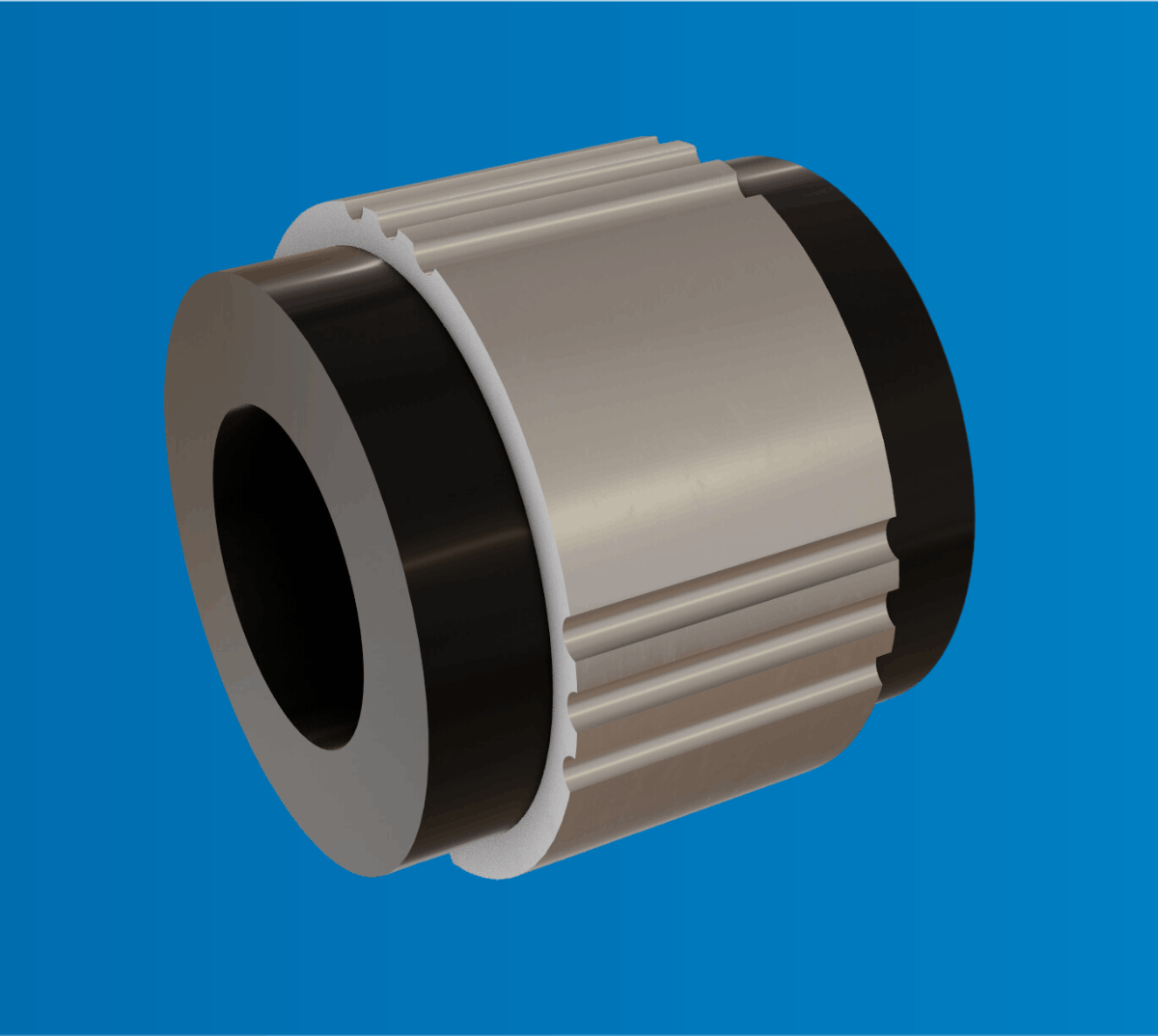

For EV Motors, Stator Coils, Transformers, Ignition Coils

Trickle Varnish Impregnation Plants

for Hub Motor, BSG, IPM BLDC, Synchronous Motor

Total control on your vacuum potting process

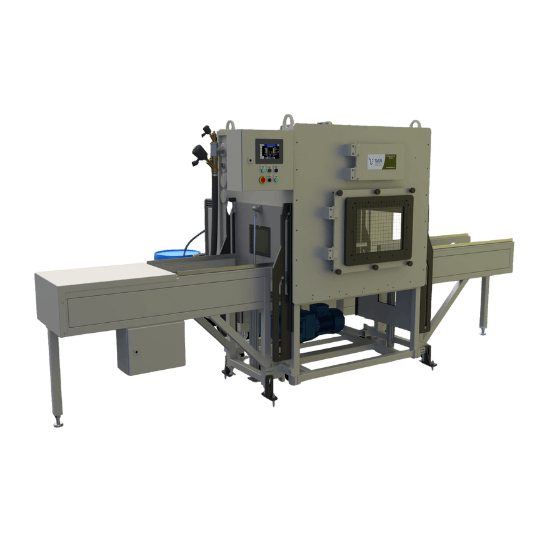

Total automation from pre-heating, potting to curing. Entire potting process with a single operator.

Vacuum Potting for Motors

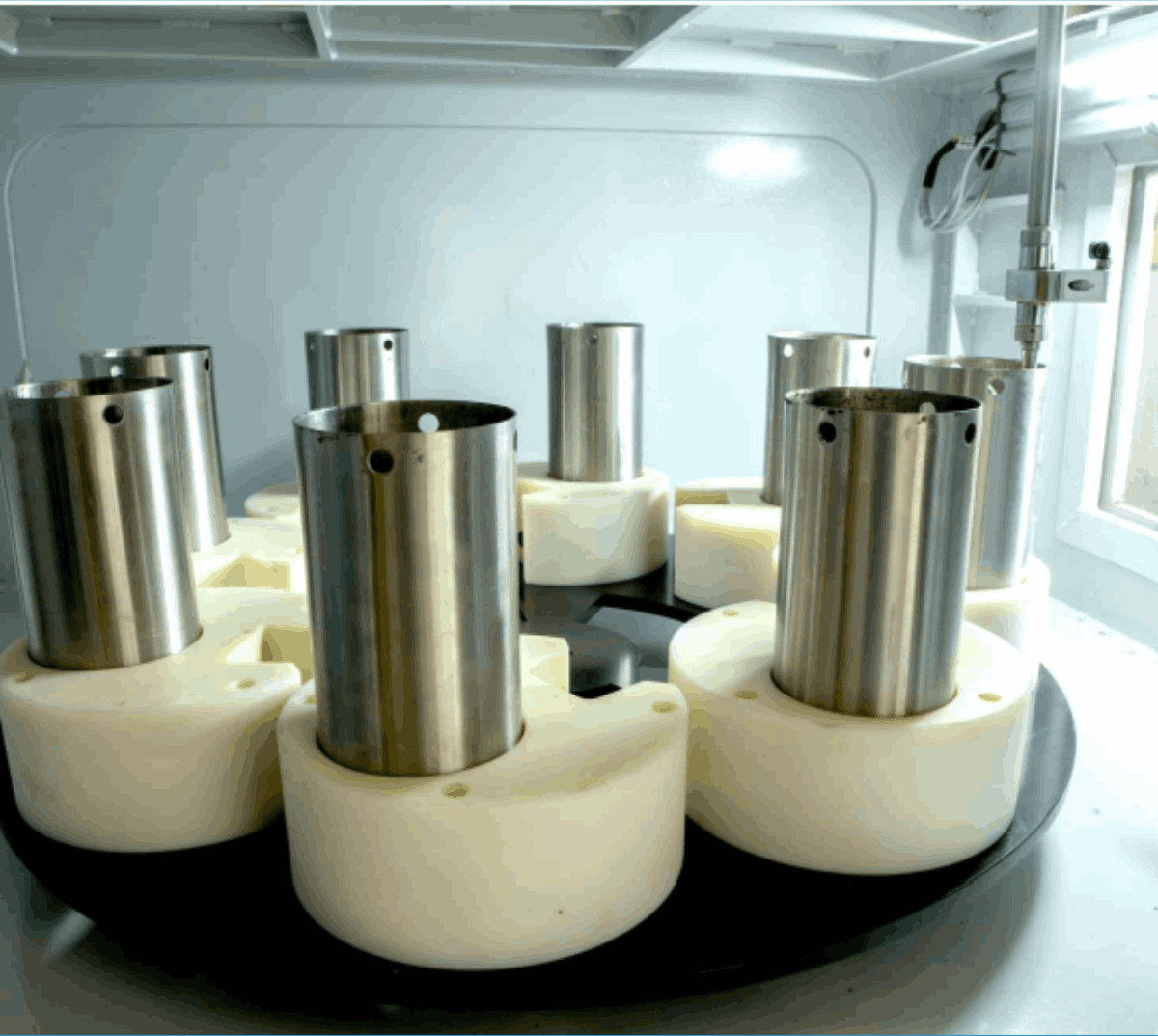

Tanks

2/3/4 Tank Systems of 5 L to 150 L

Vacuum level

Up to 1 mbar (in special applicationsup to 5 mba)

Flow Rate

0.5 g/sec to 1kg/min

Get highest reliability and efficiency for vacuum potting in motors. Benefit from 100% Performance guarantee with high durability.

Twin’s vacuum potting systems help you scale production, reduce the complexity and guarantee 100% quality for zero rejections and high performance of motors and coils.

By eliminating air pockets and ensuring complete encapsulation, vacuum potting enhances thermal management, improves insulation, and protects against environmental contaminants.

Benefit from Twin's advanced mixing and dispensing technology

100% Bubble Free Potting

Variable Ratio Systems

Processing materials with wide range of viscosities

IoT for data management and preventive maintenance

Available with a range of vacuum chambers

Operator friendly, and programmable process recipes

Easy cleaning and maintenance

24 X 7 Service Support

Download Catalog 2024

Want to browse the entire range of our products at your leisure?

Get your FREE copy of the latest Product Catalog.

Complete range, customised to your needs

Not sure where to start

Poor potting in motors can

Choose your machine with our Expert

Sanchita Bhalwankar

Expert in Potting Processes

- +91 99755 49703

- mktg@twinengineers.com